DS 3DEXPERIENCE

As a Dassault Systemes PLM development partner, and the developer of the Creo, NX, Oracle, PDMLink, and QAD integrations to ENOVIA, ITI is uniquely qualified to assist you with your 3DEXPERIENCE CAD and ERP integration needs.

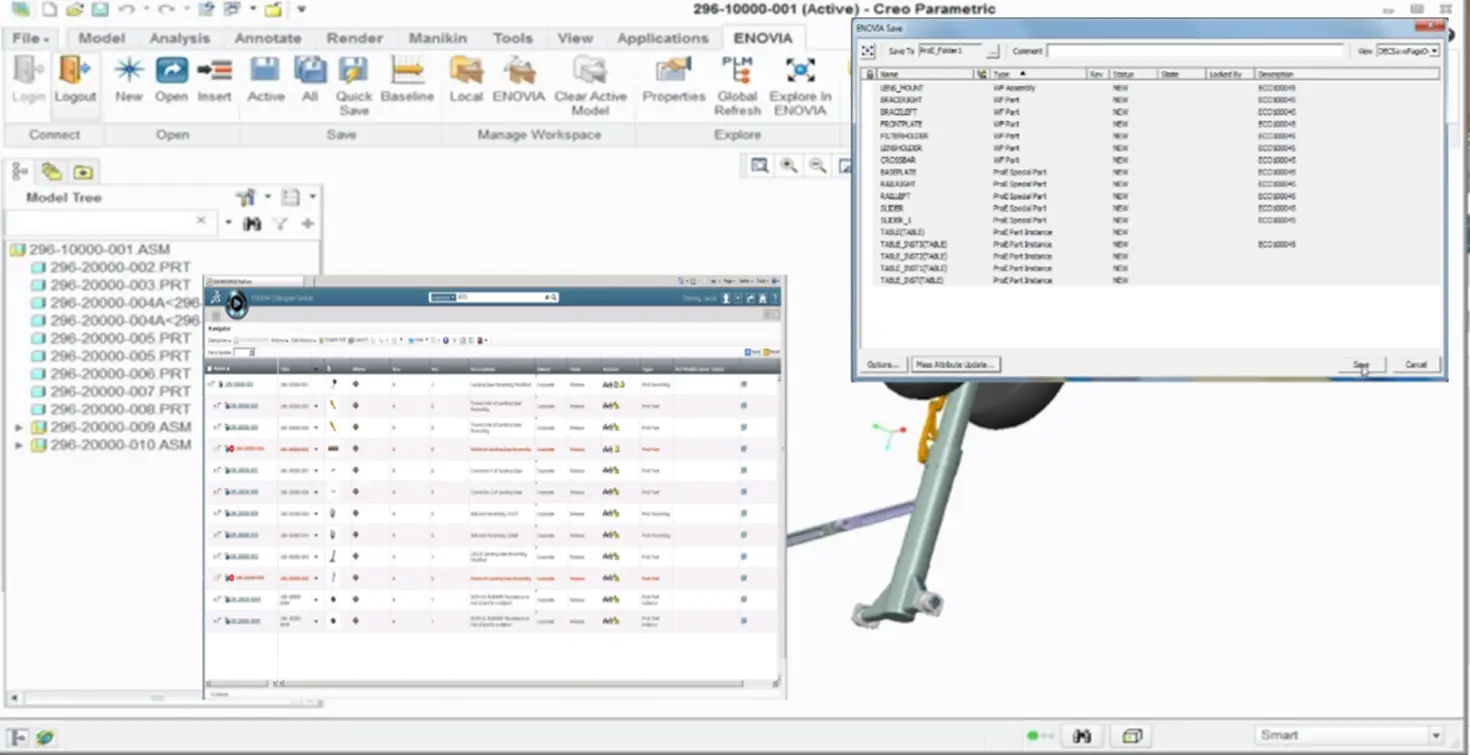

ENOVIA Creo Integration

The Creo® Integration with 3DEXPERIENCE ENOVIA® is developed by ITI and sold by Dassault Systemes.

The Creo integration connects PTC's Creo design software with ENOVIA as the system of record, enhancing efficiency and allowing users to focus on product development. It simplifies data management in ENOVIA, handling tasks like sign-offs and ECO processing virtually. Using ENOVIA as a CAD-neutral format, it provides direct data access to downstream users without disrupting CAD operations. This seamless integration ensures smooth collaboration for manufacturing, procurement, and production teams, adhering to corporate practices. ITI's expertise in Creo and ENOVIA, supported by a dedicated migration and implementation team, ensures successful project execution.

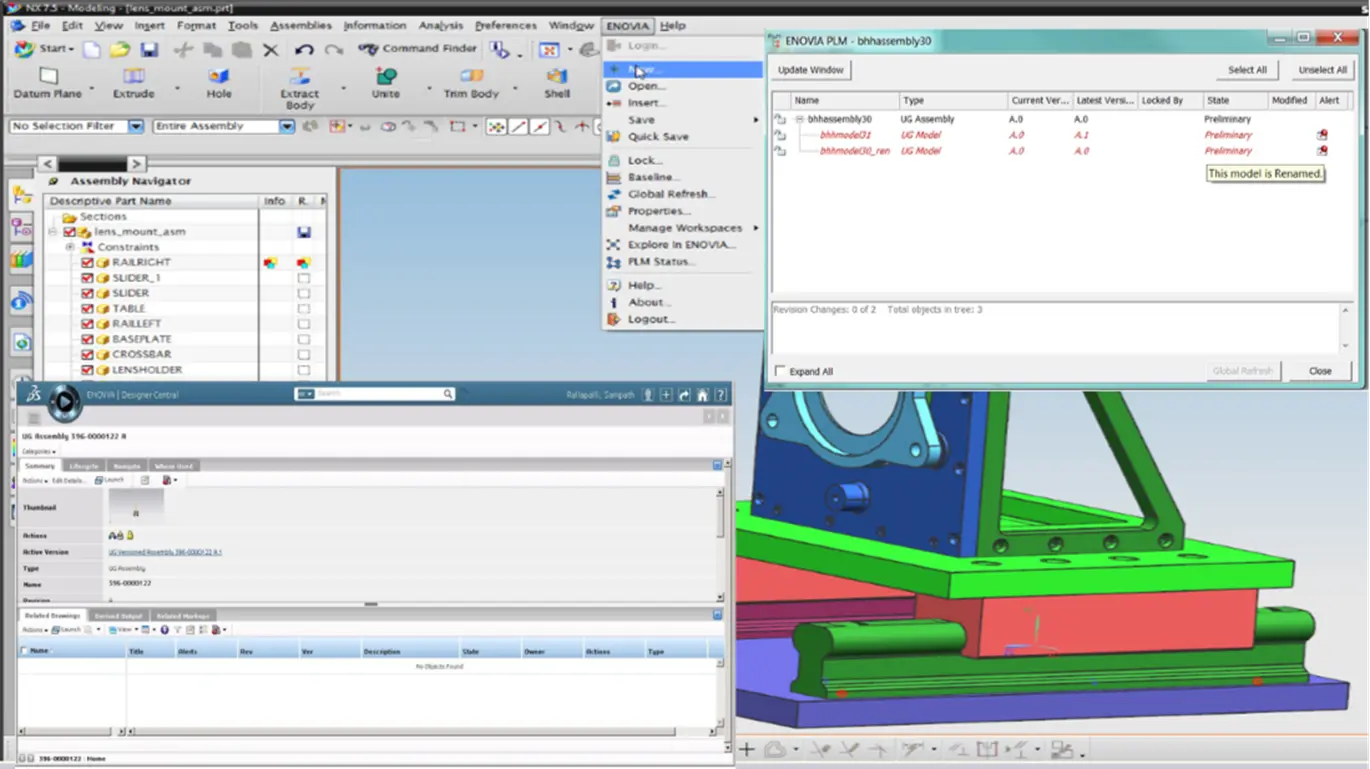

ENOVIA NX Integration

The NX® Integration with 3DEXPERIENCE ENOVIA® is developed by ITI and sold by Dassault Systemes.

The NX integration links Siemens NX design software with ENOVIA as the system of record, boosting efficiency and enabling users to concentrate on product development. It facilitates effortless data management in ENOVIA, handling tasks like sign-offs and ECO processing virtually. Utilizing ENOVIA as a CAD-neutral format, it grants downstream users direct data access without interrupting CAD workflows. This ensures seamless data consumption for manufacturing, procurement, and production teams, while adhering to corporate ENOVIA practices. ITI's extensive expertise in NX and ENOVIA, along with their dedicated migration and implementation team, guarantees successful project execution.

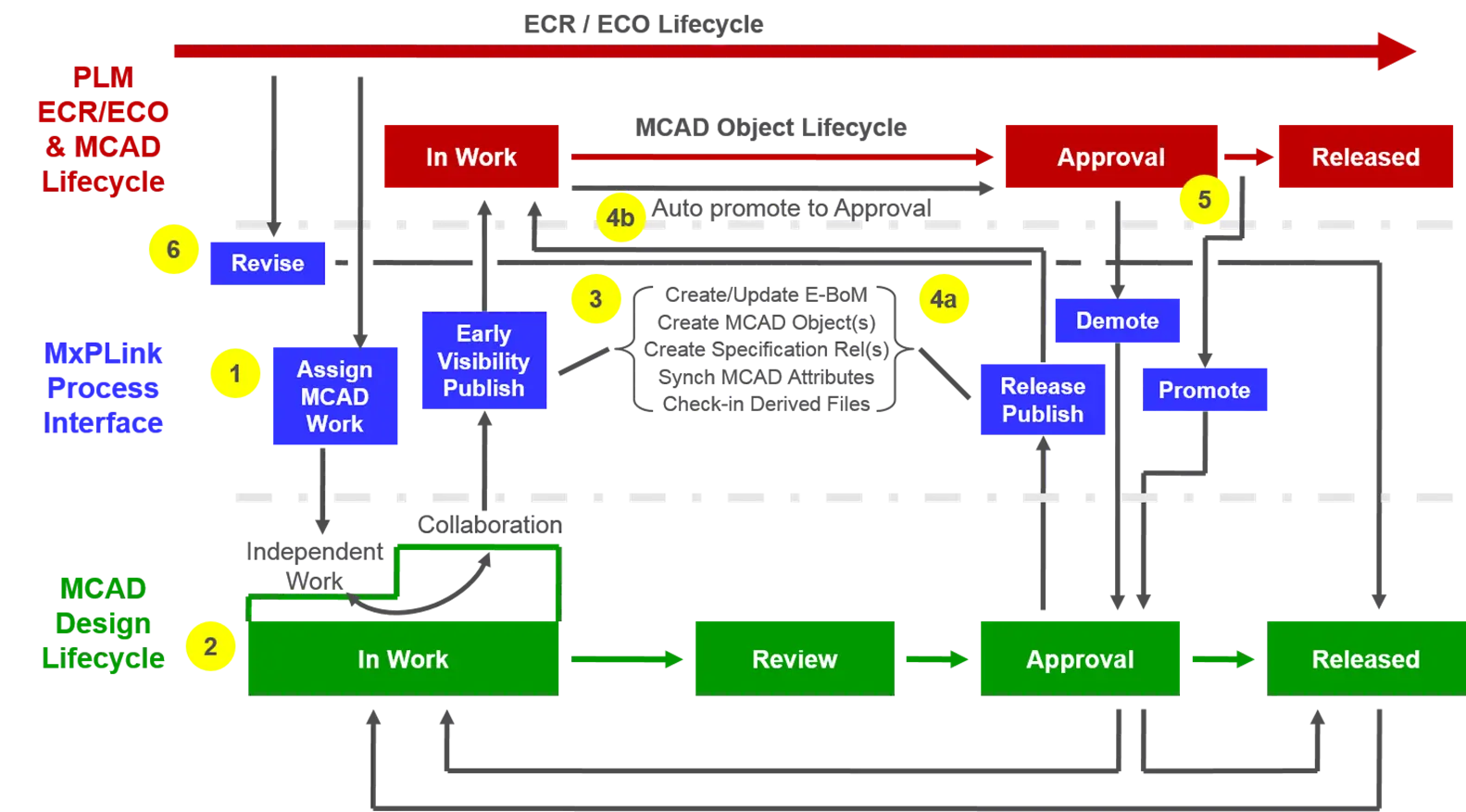

ENOVIA PDMLink Integration

The PTC Windchill® PDMLink Integration with 3DEXPERIENCE ENOVIA® is developed and sold by ITI.

ITI's ENOVIA-PDMLink integration, known as "MxPLink," automates the bi-directional flow of information between ENOVIA PLM and PDMLink. This integration allows independent use of PDMLink for MCAD WIP data management and ENOVIA for enterprise engineering release and change control. Mechanical design starts in PDMLink, with design variations iterated independently before being pushed to ENOVIA for enterprise visibility and change management. The integration synchronizes MCAD data and E-BoM, controls data access via ENOVIA, and locks down design data in PDMLink until an ENOVIA ECR is initiated or released. MxPLink packages and transfers mechanical design data for supplier exchange through ENOVIA, representing a flexible integration framework tailored to customer needs. ITI’s expertise in PDMLink and ENOVIA, along with their dedicated integration and implementation team, ensures successful project execution.

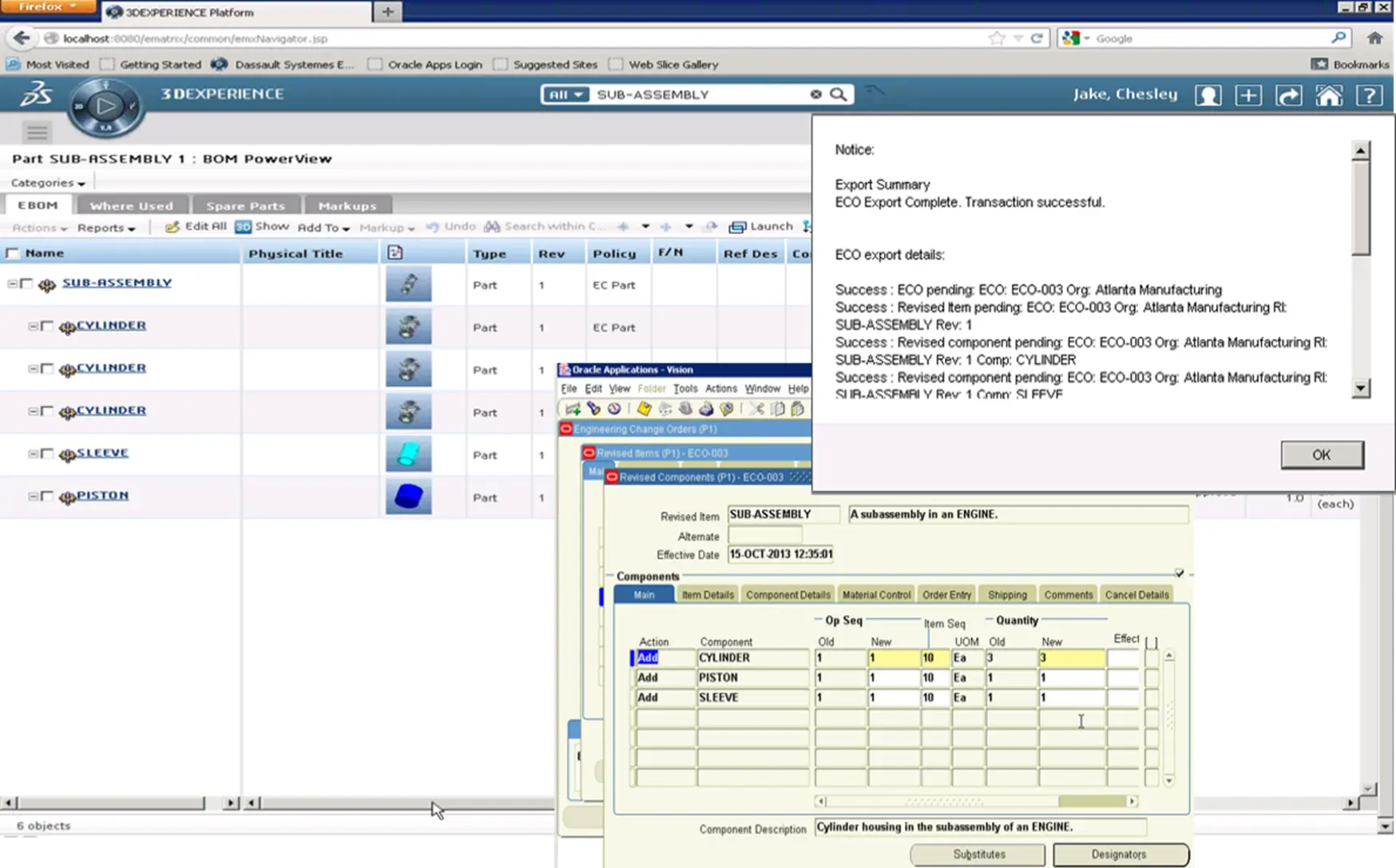

ENOVIA Oracle Integration

The Oracle® ERP Integration with 3DEXPERIENCE ENOVIA® is developed by ITI and sold by Dassault Systemes.

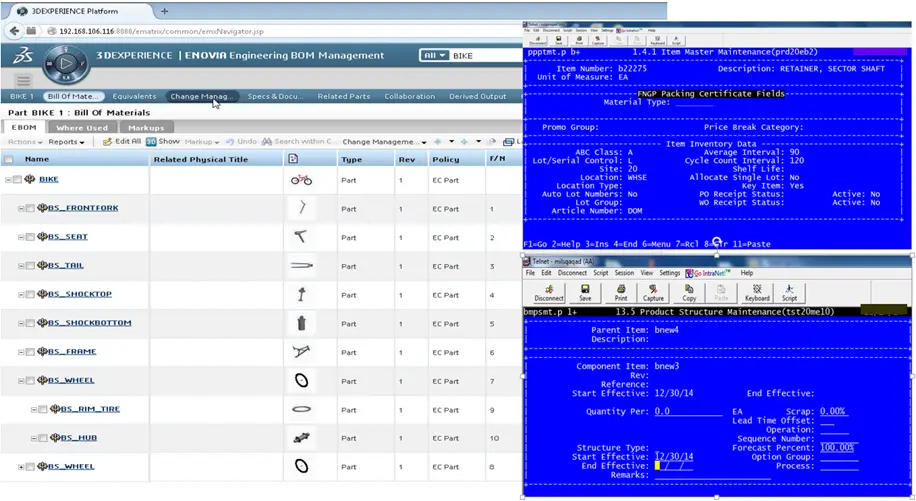

ITI's Oracle ERP integration with ENOVIA automates the bi-directional flow of information between PLM and ERP systems, eliminating data entry duplication and reducing human errors. This integration enhances process efficiency by providing a consistent change process, E-BoM management, and smooth ERP integration. It integrates product engineering with complex ERP production planning, offering early visibility to key information like cost, inventory, and item status, aiding critical decision-making. Frequent engineering changes are seamlessly managed, accelerating time to market. ITI's expertise in Oracle and ENOVIA, along with their dedicated integration and implementation team, ensures successful project execution.

ENOVIA QAD Integration

The QAD® ERP Integration with 3DEXPERIENCE ENOVIA® is developed and sold by ITI.

ITI's ENOVIA-ERP integration automates the bi-directional flow of information between ENOVIA PLM and QAD ERP systems, eliminating data entry duplication and reducing human errors. This integration enhances process efficiency by offering consistent change processes, E-BoM management, and ERP release processes. It seamlessly integrates product engineering with complex ERP production planning, providing early visibility to key information like cost, inventory, and item status for critical decision-making. Frequent engineering changes are smoothly managed, accelerating time to market. ITI's expertise in QAD and ENOVIA, along with their dedicated integration and implementation team, ensures successful project execution.

ITI Integration Implementation Consulting

As an Aras, Dassault Systems, and Siemens integration development partner, ITI is uniquely qualified to assist you with your integration implementations.

We've developed a step-by-step integration implementation methodology to ensure that your future PLM/CAD/ERP implementation will meet your business needs. Our integration methodology is scalable and extensible to address the unique needs of your business. Trust ITI for a seamless and successful integration journey.